How to Judge Permanent Magnet Products

Magnetic materials mainly include permanent magnetic materials, soft magnetic materials, magnetic materials, special magnetic materials, etc., covering many high-tech fields. In the fields of rare earth permanent magnet, permanent magnet, amorphous soft magnetic material, soft magnetic ferrite, microwave ferrite device and magnetic material special equipment technology, a huge industrial group has been formed all over the world.

NdFeB permanent magnets are also called modern industrial monosodium glutamate. As an important modern industrial magnetic material, it promotes the progress of modern technology and society. It is widely used in various fields. How to determine the quality of permanent magnets in an all-round way?

1. Magnetic energy

First of all, the key to the decision is to control the magnetic properties of the raw materials in the production process.

1, raw material manufacturers produce suitable sintered NdFeB according to their business requirements, and purchase raw materials that meet national standards.

2, the advanced nature of the production process also determines the quality and performance of the magnet.

3, quality control in production is very important.

Two, the shape and size of the magnet and the tolerance value

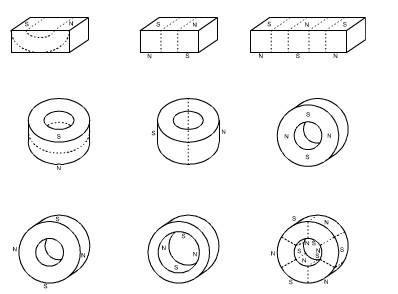

The shapes of NdFeB magnets are round, irregular, square, tile and trapezoidal. Different sizes of materials are machined by different machine tools for cutting rough materials. Advanced technology and machine operators determine the accuracy of the product.

Three, surface coating treatment

The plating quality of surface coating, zinc, nickel, nickel copper nickel plating copper and gold plating process. The plating options can be done according to the customers' requirements. A brief summary of the quality of NdFeB products is to grasp the performance, size tolerance control and judge the appearance of the coating. Test magnets magnetic flux Gauss surface, and other tests; dimensional tolerance, can be measured with the vernier caliper precision; coating color and brightness and coating binding force, and can observe the surface of the magnet, or no edge drop angle by appearance, to evaluate the quality of the product.

Pre: How NdFeB Magnets are Made

Next: The Application of Superconducting Magnetic Levitation