The Application of Superconducting Magnetic Levitation

Magnetic levitation train is regarded as one of the most promising high-tech transportation means in twenty-first Century, because of its safety, stability, adaptability to the environment, high speed and suitable for a large number of transportation. In order to seek the balanced development of land and economy, and to drive the development of various related industries through the development of superconducting magnetic levitation technology, Japan has started the preparatory work of the linear motor to promote the suspension mode of the train since 1962. On February 10, 1999, with the success of the 5 section of the 500 kilometer load of 270 people in shamanshan County, Japan, the basic development plan of the Japanese superconducting maglev train was close to the end, and it would be transferred to the development and construction stage of the commercial operation line.

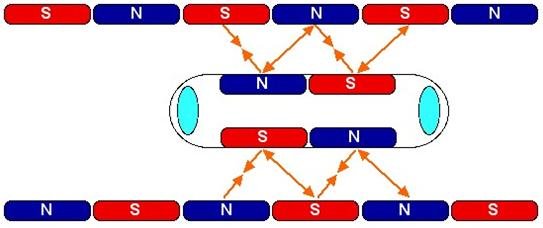

Superconducting coil: superconducting coil is one of the most important equipment of maglev train, which enables the train to get up, push and guide. The superconducting material used in Japan is a superconducting wire made of the superfine niobium titanium alloy multi core wire embedded in the copper bus. When the superconducting wire is immersed in the liquid helium (- 269 C), it enters the superconducting state and produces a powerful magnetic field. This is the first time in the world to use a superconducting technology on a practical transport device to achieve a high power strong NdFeB magnets and magnetic coil with a speed of 550 kilometers per hour, with a voltage of 22KV.

Vehicle cryopreservation system: each vehicle mounted strong magnetic unit is equipped with a liquid helium and a liquid nitrogen compression refrigerator respectively. The function of the liquid helium compressor is to re - refrigerate helium, which is gradually vaporized by external heat energy and the heat generated by the train itself, into liquid helium. The function of the liquid nitrogen compression refrigerator is to re cool the liquid nitrogen refrigerant of the external heat insulation plate of the cooling superconducting coil, and maintain the state of low temperature liquid nitrogen at the temperature of 19. 6 C. The compressor equipped with MLX01 train is the smallest and most powerful energy saving type of liquid helium and liquid nitrogen compressor in the world, and it has achieved a record of 10 thousand hours without fault. When the train is running, it does not need to replenish liquid nitrogen or liquid helium once it is filled with helium (nitrogen).

Pre: How to Judge Permanent Magnet Products

Next: Complete Diamagnetic - The Most Important Feature of Superconductors